Smart H2E Hub

Our goal is to solve the problem of available Green Hydrogen where the vehicle needs it. Green Hydrogen is considered expensive. Huge Production Plants are currently being built or planned, but they are far away from the actual demand and won’t go into operation for some years.

We invented an efficient way to use available electric energy from renewable sources such as Solar and Wind and convert them to green Hydrogen whenever it is supporting the path to a decarbonized economy.

Our patent pending MFH25 Technology combines state of the art of Electrolyzer Technology with the dynamics of Electric Energy Storage Systems. The output is Green - yet competitive - Hydrogen, Heat Energy, and even Offgrid Electical Energy on Demand.

Dedicated Onsite Systems are available starting at a daily demand of average 500Kg H2. Flexible Subscription models start at 50Kg per day.

Solutions we offer

Green Hydrogen and Power-to-X plant development

Assisting hydrogen and PtX developers in the cost-effective and safe production and transportation of low-

carbon hydrogen and its derivatives.

Our services include feasibility studies, consulting, planning, process making, procurement, efficient plant designing, constructing, EPC and managing hydrogen and power to X facilities.

Services

Feasibility Studies and Financial Analysis

We understand the difficulties involved in delivering bankable projects, managing supply chain and technology selections, and optimizing your project to create competitive offtake opportunities. Our studies support your decision-making process, helping you quickly identify suitable solutions for further development while keeping costs minimal and maximum profit.

-

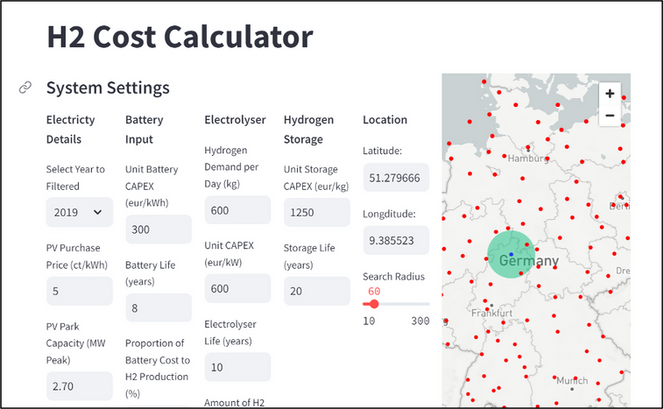

We have developed a simulation model designed to calculate the optimal sizes for components of a green hydrogen plant, such as electrolyzers, batteries, and hydrogen storage, compressors while considering the techno-commercial aspects of the whole project.

-

This tool is equipped with the intelligence to predict renewable energy generation for any location and inheritance the behavior of the plant components.

-

Additionally, we maintain an in-house database of different suppliers for Green H2 plant components, these features enable us to compare costs associated with different component manufacturers.

Optimizing the component sizes and eventually the profitability

Our simulation model inherited with advanced intelligence allows us to achieve the lowest Levelized Cost of Hydrogen (LCOH).

H2 supply chain database

Advantage of our extensive experience in green energy projects and global supply chain database of green hydrogen projects

Prediction of renewable energy generation of any location

Our machine learning model enables the prediction of renewable energy generation at any location.

Products

MultiFlowH25

The core of our innovation is our Greenbox MultiflowH25 intelligent control system that applies power balancing algorithms based on self-learning smart predictive models to ensure the most productive system operation. Greenbox MultiflowH25 generates productivity advantages with an impressive result of up to 25% total cost improvement to locally produce green hydrogen.

The MultiFlowH25 System determines the specific dimensions for each component in Power to Gas (PtG) installations so that attractive business models with a long-term profitability and sustainability are guaranteed. Each of our applications is absolutely fitted to the individual use case. The starting point for such a system can either be demand driven for example by the customers yearly demand for H2 or based on supply capacity and profile for example around an already active renewable energy source (e.g. wind, solar, hydro). After determining the perfect fit for the specific use case, Greenbox will provide a complete implementation proposal including the complete business plan from investment scheme to operational model and costs.

The key innovation of our MultiFlowH25 System is to keep the interplay between the dynamic load curve of a RES, the power sourcing for a downstream energy storage system (ESS), the PtG and GtP components and hydrogen storage at its highest efficiency in regard to the economy, the life cycle of the whole system and the maximization of H2 production. Applying such a system optimization, we are the enabler for a new generation of business models in energy management.

Our systems are fully connected: real-time data from all our systems are collected and analyzed for a continuous improvement process concerning system efficiency and lowering cost through predictive maintenance. Data analytics constantly keep our systems on the peak of their efficiency and environmental data forecasting (weather, supply, demand, pricing) is pushing the system way ahead of competition. The users of the Greenbox MultiFlowH25 system will always benefit from the newest technologies on the market.

What can you expect from us: We either build your customized Plug&Play H2 Power Plant or enter into a purchase power agreement (PPA) with you to secure your energy market business model.

Use Cases

Second Life Energy Plants

Renewable energy power plants, which have lost their claim to the EEG apportionment after 20 years, are facing the crucial decision of either continuing their operation of feeding electricity into the grid, but at a much lower remuneration (often below the breakeven point), or completely dismantling the power plant at a significant cost.

Greenbox offers a very attractive solution to continue operation with the prospect of getting high and stable returns that ensure operational profit for another 10 to 20 years. This alternative is based on the production of green hydrogen from the renewable energy power plant. For this use case, Greenbox offers a complete plug-and-play solution either as an investment addition to the existing facility or as a PPA model.

Grid Balancing

Another use case based on the production of hydrogen is to offer a grid balancing service to the public grid. Grid balancing is when excess electricity from the grid is locally stored (in our application in form of H2) and then fed back into the grid as soon as demand for electricity exceeds supply. Grid balancing will increasingly become a necessity as the percentage of renewable energy rises in the energy mix. Demand for energy in the grid does not overlap with the real-time supply from renewable energy, so a form of energy storage is an absolute necessity. While hydrogen is widely regarded as the future solution of energy storage, our Greenbox MultiflowH25 system makes hydrogen the solution of your Grid balancing business model today- competitive, sustainable, reliable and feasible.

Emission-free CHP Solution

Fuel Cells convert Hydrogen back to Electricity. But in addition to Electricity also heat is being generated. This builds the basis for combined heat and power (CHP) solutions. For this use case, we are able to plan and implement a complete system combining on-site upstream production of hydrogen with Electrolyzers and a stationary fuel cell for the conversion of hydrogen to electricity and heat. Due to the simultaneous usage of electricity and heat, the parametrics of the fuel cell can be ideally utilized so that system efficiencies close to 100% are feasible. This whole process would take place without generating one single gram of CO2. Our MultiflowH25 system will always ensure an optimized energy and heat supply to match the demand profile.